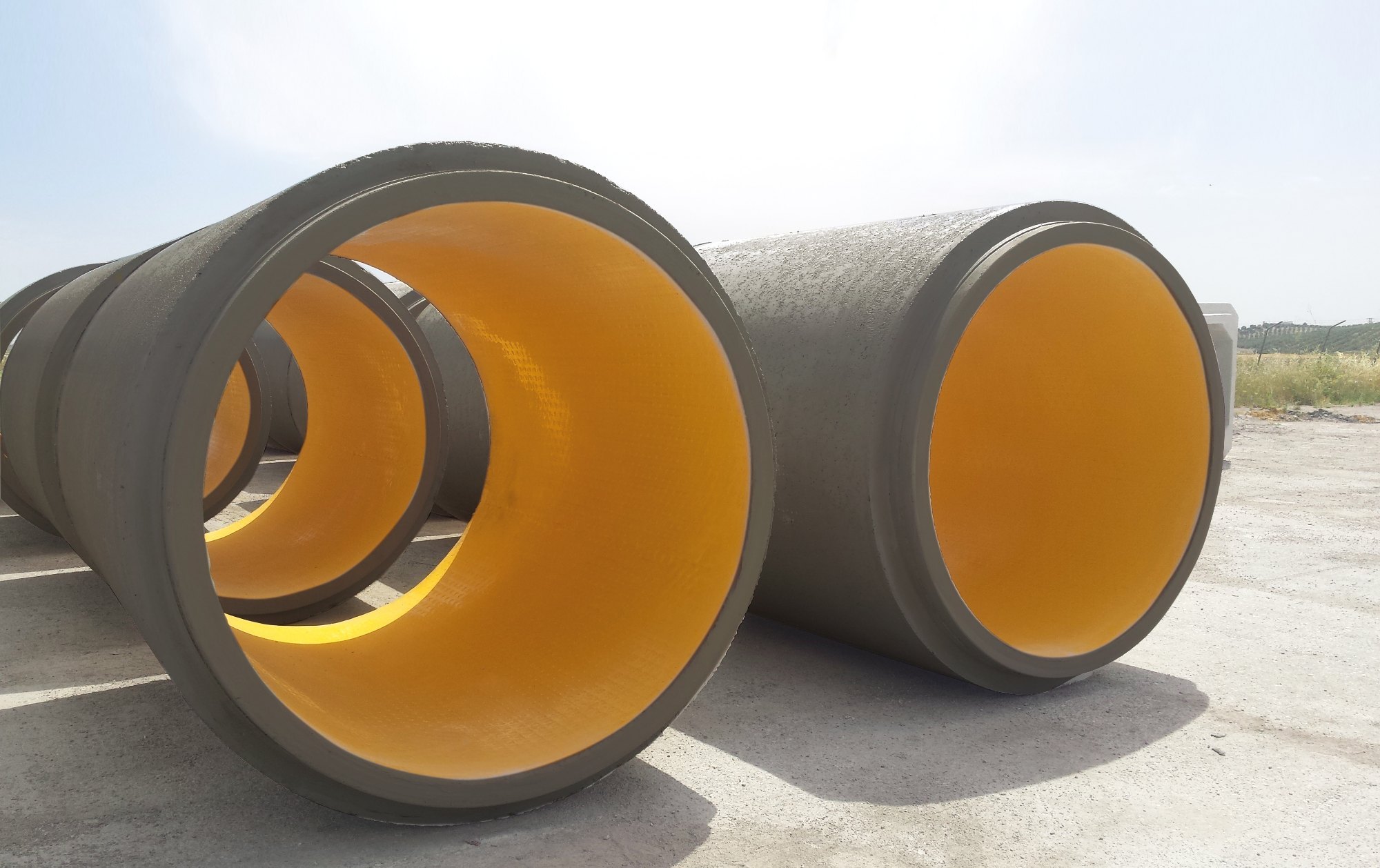

Concrete anti-corrosion service involves applying protective coatings or treatments to prevent steel reinforcement from rusting.

It blocks chemical agents like chlorides, sulfates, and acids from reaching the rebar through the concrete.

This prevents internal cracking, spalling, and structural weakening caused by corrosion.

Ideal for chemical plants, coastal structures, and sewage systems exposed to aggressive environments.

Supply Type :