Concrete Hydro Demolition: The Future of Concrete Removal

Eco-friendly, vibration-free demolition for modern infrastructure.

Concrete is one of the strongest construction materials in the world — but even the strongest materials eventually require repair or replacement. Traditional demolition methods often involve jackhammers or heavy machinery, which can cause unnecessary vibrations, dust, and micro-cracks that damage the surrounding structure.

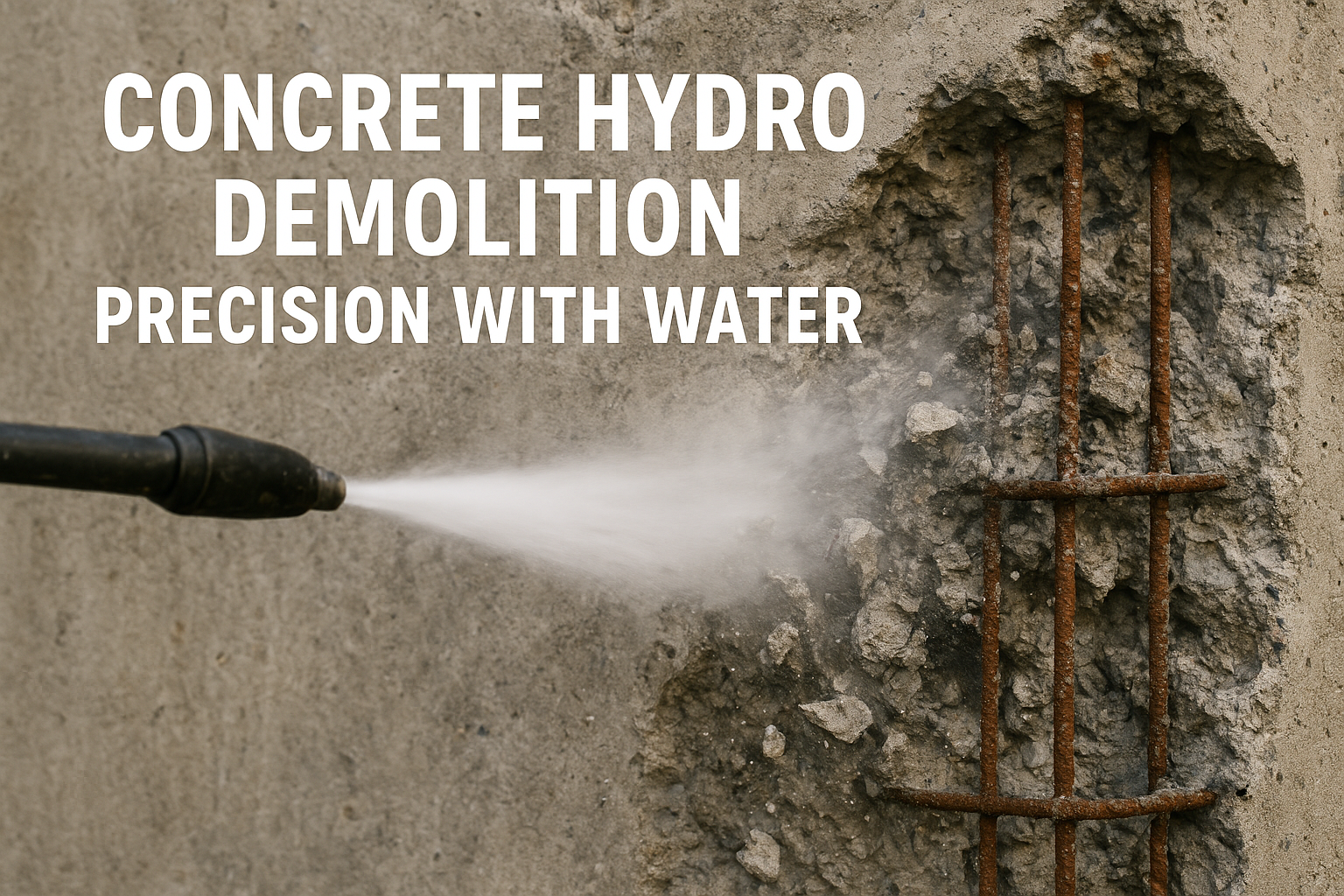

This is where Concrete Hydro Demolition comes in. Using the power of high-pressure water jets, hydro demolition provides a precise, safe, and eco-friendly way to remove concrete without harming the reinforcement or nearby areas.

Let’s explore this technology in detail.

What is Hydro Demolition?

Hydro demolition (also called hydro blasting or hydro milling) is a technique where ultra-high-pressure water jets (usually ranging from 1000 to 2500 bar) are directed at a concrete surface.

The water penetrates and breaks down the cement matrix, causing the concrete to disintegrate. Unlike mechanical demolition, it leaves rebar, steel reinforcements, and surrounding structures intact.

Types of Hydro Demolition

There are two main methods, depending on the scale of work:

1. Handheld Hydro Demolition

-

Carried out with portable water jetting equipment.

-

Best for small repair areas (like removing damaged patches on bridges or floors).

-

Offers precise control and is useful in confined spaces.

2. Robotic Hydro Demolition

-

Uses remotely controlled robots fitted with high-pressure nozzles.

-

Ideal for large-scale projects like bridge decks, tunnels, dams, and parking structures.

-

Ensures speed, consistency, and worker safety.

Advantages of Hydro Demolition

-

Preserves Structural Integrity

-

Removes only the damaged or weak concrete while keeping strong concrete intact.

-

Reinforcement bars remain undamaged and even get cleaned for better bonding.

-

-

No Micro-Cracks or Vibrations

-

Unlike jackhammers, it doesn’t introduce vibrations that weaken the structure.

-

-

Better Bonding for Repair Materials

-

Creates a rough surface profile ideal for new concrete overlays, repair mortars, or coatings.

-

-

Eco-Friendly

-

Reduces dust and noise pollution.

-

Water used can often be filtered and recycled.

-

-

Worker Safety

-

Robotic systems reduce manual handling and exposure to harmful dust.

-

Applications of Hydro Demolition

Hydro demolition is widely used in:

-

Bridge Deck Repairs – Removing damaged concrete while keeping rebar intact.

-

Tunnels & Dams – Selective removal in sensitive environments.

-

Parking Garages – Repairing floors and ramps without affecting structure.

-

Marine Structures – Jetty, port, and harbor concrete repair.

-

Industrial Floors – Preparing surfaces for overlays or coatings.

Hydro Demolition Process Step by Step

-

Inspection & Marking – Identify areas of weak/damaged concrete.

-

Setup – Position the hydro demolition machine or handheld lance.

-

Concrete Removal – Apply high-pressure water jets to disintegrate weak concrete.

-

Reinforcement Cleaning – Rebars are automatically exposed and cleaned during the process.

-

Waste Handling – Collect and filter water slurry to separate aggregates and recycle water.

-

Surface Preparation – Resulting surface is ready for fresh concrete or repair mortar application.

Limitations of Hydro Demolition

-

High Water Requirement – Needs significant water supply and proper disposal systems.

-

Equipment Cost – Machines and pumps are expensive compared to traditional tools.

-

Skilled Operators Needed – Requires trained personnel for efficiency and safety.

The Future of Concrete Removal

With increasing emphasis on sustainable construction and long-lasting repairs, hydro demolition is becoming the preferred method worldwide. Its ability to extend the life of existing infrastructure while reducing environmental impact makes it a key technology in modern civil engineering.

Concrete hydro demolition is revolutionizing how we approach repairs, retrofitting, and demolition. By using high-pressure water jets instead of traditional mechanical tools, it ensures precision, safety, and durability.

Whether it’s a bridge, tunnel, or high-rise structure, hydro demolition not only preserves what’s strong but also prepares a perfect surface for the next phase of construction.

Truly, it represents the future of concrete removal and repair.