Concrete Carbonation: Causes, Effects, and Prevention

Concrete is one of the most widely used construction materials in the world due to its strength, durability, and versatility. However, like any material, concrete is not immune to deterioration. One of the most common issues affecting reinforced concrete structures is carbonation. This natural process can reduce the durability of concrete and put steel reinforcement at risk of corrosion, ultimately threatening the long-term performance of structures.

In this blog, we’ll explore what concrete carbonation is, how it happens, its effects, and the preventive measures that can be taken.

What is Concrete Carbonation?

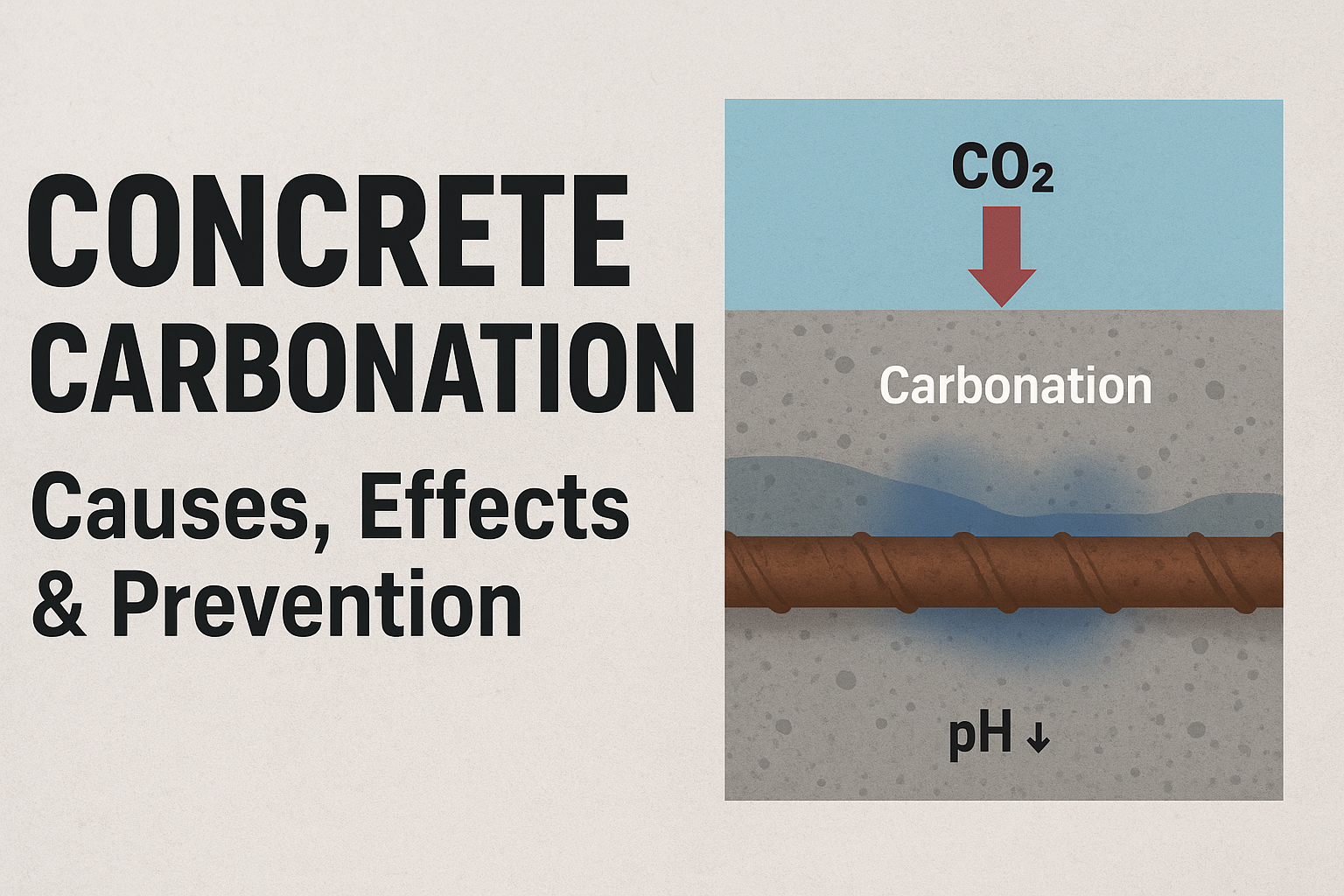

Concrete carbonation is a chemical process where carbon dioxide (CO₂) from the atmosphere penetrates into the concrete and reacts with calcium hydroxide (Ca(OH)₂) present in the cement paste.

The chemical reaction can be simplified as:

Ca(OH)2+CO2→CaCO3+H2OCa(OH)₂ + CO₂ → CaCO₃ + H₂O

This reaction forms calcium carbonate (CaCO₃) and lowers the alkalinity (pH) of concrete. Normally, concrete has a pH around 12.5–13.5, which protects the embedded steel reinforcement from corrosion. When carbonation lowers the pH below 9, the passive protective layer on steel breaks down, and corrosion begins.

Causes of Concrete Carbonation

-

Atmospheric CO₂

-

The primary cause is the presence of CO₂ in the air. In urban and industrial areas, higher CO₂ levels accelerate carbonation.

-

-

Moisture Content

-

Carbonation occurs most rapidly in concrete with a relative humidity of 50–70%. Too dry or too wet concrete slows the process.

-

-

Concrete Quality

-

Low cement content, high porosity, and poor compaction make concrete more vulnerable.

-

-

Cover Depth

-

If the concrete cover over reinforcement is too thin, carbonation reaches the steel quickly.

-

-

Age of Concrete

-

Newly cast concrete carbonates slowly, but as micro-cracks develop with age, carbonation depth increases.

-

Effects of Carbonation in Concrete

-

Loss of Alkalinity

-

Reduction in pH leads to the breakdown of the passive layer that protects steel.

-

-

Steel Corrosion

-

Once the protective layer is lost, reinforcement begins to rust. Rust expands, causing cracks and spalling in concrete.

-

-

Reduced Durability

-

Carbonated concrete loses strength and becomes more brittle over time.

-

-

Structural Damage

-

Long-term carbonation can lead to serious structural issues, especially in bridges, parking structures, and high-rise buildings.

-

How to Test Carbonation in Concrete?

-

Phenolphthalein Test

-

The most common test. A freshly broken concrete surface is sprayed with a phenolphthalein indicator solution.

-

Uncarbonated concrete turns pink/purple (high pH), while carbonated areas remain colorless.

-

-

Carbonation Depth Measurement

-

Used to determine how far carbonation has penetrated compared to the reinforcement cover.

-

Prevention of Concrete Carbonation

-

Good Quality Concrete Mix

-

Use adequate cement content, proper compaction, and curing to reduce permeability.

-

-

Sufficient Cover Depth

-

Provide proper concrete cover as per IS 456, ACI, or other codes to protect reinforcement.

-

-

Protective Coatings & Sealers

-

Surface coatings, paints, and hydrophobic sealers reduce CO₂ and moisture penetration.

-

-

Use of Supplementary Cementitious Materials (SCMs)

-

Fly ash, silica fume, and slag can refine pore structure, reducing carbonation risk.

-

-

Regular Maintenance

-

Inspect concrete structures periodically and repair cracks promptly to avoid CO₂ ingress.

-

Concrete Carbonation vs Chloride Attack

While carbonation reduces alkalinity and initiates corrosion, chloride attack directly breaks down the passive film on steel, even in high pH conditions. Both are major causes of reinforced concrete deterioration, often acting together in aggressive environments.

Concrete carbonation is a slow but serious process that can compromise the durability and safety of reinforced concrete structures. By understanding its causes, testing methods, and preventive measures, engineers and builders can ensure longer service life for concrete infrastructure.

At Concretewale.com, we bring together information, products, and solutions to help the construction industry combat challenges like carbonation and build stronger, more durable structures.